Model predictive control of mechatronic systems

Motivation and goal

For fast and precise control of mechatronic systems, especially in industrial applications, mostly cascaded control concepts based on PID controllers are used. The individual PID controllers are extended with nonlinear characteristics for integral and proportional gain to meet the system behavior requirements. These control designs have a high number of coupled controller parameters. Thus, the controller design is not intuitive and mostly requires the use of automated evolutionary hardware-in-the-loop optimization. A subsequent adaptation of the system behavior is only possible by a process expert. Thus, a universal control concept is sought, which is guaranteed to be real-time capable, provides a high control quality and allows an intuitive manual controller design. In addition, position and state constraints should be explicitly observed. Often the outer controller of an existing cascade shows the highest complexity. For a low implementation effort, the outer controller should be replaced and the remaining control loop should be maintained.

Model predictive control

Model predictive control represents an advanced control concept. In each sampling step, an optimal control problem is solved. Thereby, the future system behavior is predicted over a limited moving horizon. To realize and adapt this control for real-world applications, the engineer must be familiar with numerical discretization methods, nonlinear optimization, and efficient implementation to meet real-time constraints. This research project focuses, among other things, on the development of model predictive control schemes without the use of derivative-based optimization algorithms. In addition, to reduce computation time, the degrees of freedom during prediction are severely constrained. The result is real-time model predictive control for systems with small sampling times. Practical development focuses on simple implementation and intuitive controller design [1]. Methodological development focuses on ensuring important control properties such as forward invariance and asymptotic stability [2].

Model predictive control in holistic optimization of mechatronic systems.

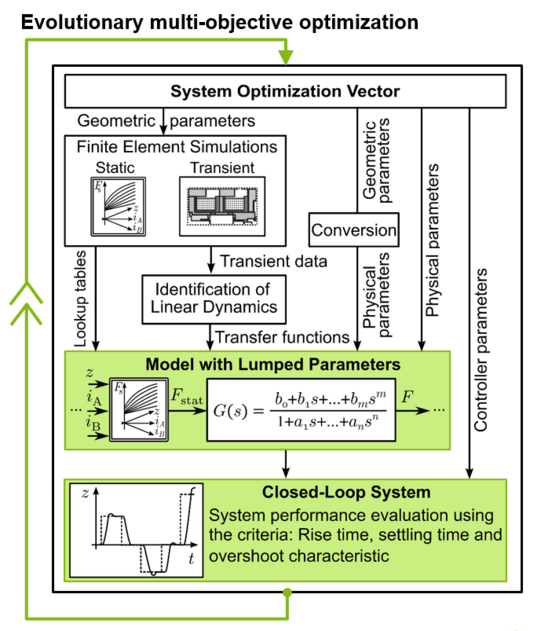

In addition to the control of real processes, model predictive control is also suitable for holistic system optimization. The interaction of components from different domains contributes significantly to the performance of mechatronic systems. Holistic system simulation and optimization makes it possible to coordinate the subsystems at an early stage of development. During optimization, numerous parameter combinations are tested and evaluated. The optimization variables can correspond to design parameters or general physical quantities. Since the performance of mechatronic systems is often evaluated on the basis of control quality, the controller parameters thus also represent optimization variables. As soon as the optimization algorithm makes changes to the design of the mechatronic system in an iteration (see Figure 1), the system behavior of the virtual prototype changes. To avoid evaluating the robustness of the controller, the controller must be redesigned in each new iteration based on different criteria. This procedure is very time consuming and does not allow fully automated development of new prototypes. However, model predictive control allows new prototypes to be developed without human intervention. In each iteration of the system optimization, a new nonlinear model of the entire controlled system is determined. This in turn can be used to be used as part of the model predictive control itself. By continuously updating the model, the control scheme automatically adapts to the new system behavior. Although the control performance is used as the basis for evaluation, the controller design can be largely removed from the virtual development process. The overall model cannot satisfy smoothness requirements. One reason for this is, for example, the use of piecewise linear characteristic maps. For this reason, model predictive control with derivative-free optimization algorithms are particularly suitable [3]. The developed holistic system optimization has already proven to be forward-looking in the virtual development of hydraulic directional control valves in the context of Industry 4.0 [4].

[1] A. Makarow, M. Keller, C. Rösmann, and T. Bertram, "Model predictive trajectory set control with adaptive input domain discretization," in American Control Conference (ACC), 2018.

[2] A. Makarow, C. Rösmann, and T. Bertram, "Single Degree of Freedom Model Predictive Control with Variable Horizon," in American Control Conference (ACC), 2020.

[3] A. Makarow, J. Braun, C. Rösmann, G. Schoppel, I. Glowatzky, and T. Bertram, "Introduction of Model Predictive Control for the System Optimization of a Proportional Directional Control Valve," in IEEE Conference on Control Technology and Applications (CCTA), 2018.

[4] S. Haack, "Hydraulics for the factory of the future," in Der Konstrukteur, September 2018 issue.

![[Translate to English:] [Translate to English:]](/storages/rst-etit/_processed_/e/8/csm_Technologie_RST_2018_339_a0a62aaa2f.jpg)